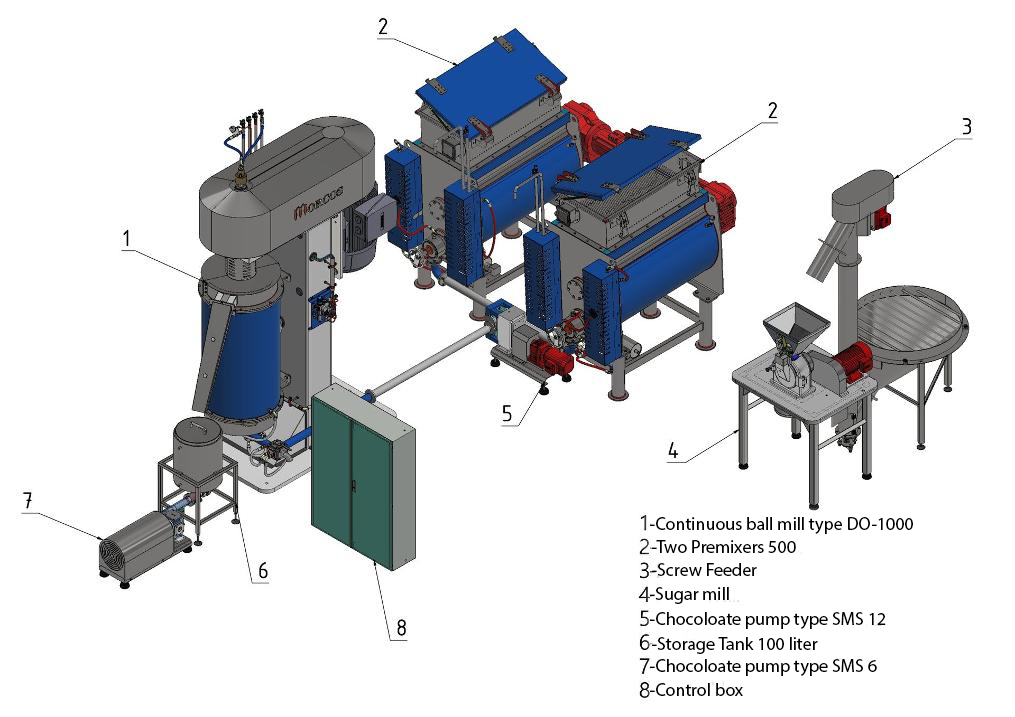

Mixer/Grinder type DO 1000

The plant consists of :

-Three screw feeders type SF, each with vibrating hopper & capacity up to 1000 kg/h

-One Turbo sugar mill type CS 500 capacity 300 – 500 kg/h

-Two pre-mixers type PREMIX 500 batch capacity 500 kg each

-Alternatively ( depending on the type of chocolate)

-Two Dry Conches type MLDC 500 batch capacity 500 kg each

-One Feeding pump Type SMS 12 to feed the mass from the mixer(s) to the ball mill

-One Ball mill DO 1000 for continuous production capacity up to 1000 kg/h

-One collecting tank AWK 100 capacity 100 lt with level detection

-One discharge pump type SMS 6 to feed the product from the collecting tank to the process line

-One water heater circulator system with own water pump and temperature control

-One control panel with PLC and touch panel

Specifications

DO 1.000

The DO 1000 produces 1.000 kg per hour using powdered sugar max. 120 micron to obtain an end fineness of 20- 25 microns based on recipe and ingredients.

Production process

The pre-mixed mass pumped from pre-mixer / dry conch, enters in bottom of the grinding vessel and final product leaves from the outlet pout in to the collecting vessel. The refining action is accomplished by a special cooled shaft with agitator arms rotating in a vertical, jacketed grinding tank filled with especially hardened steel balls.

Collecting vessel 100 Lt.,

Collecting product from outlet ball mill

•Stainless steel 304 jacketed tank

•Net volume 100lt.

•Manual operated 2-way valve

•Jacketed stainless steel piping

•High / low level system

Feeding / Discharge pumps:

One pump for feeding the ball mill from the premix/dry conch, with adjustable speed

A second pump for discharging the product from the collecting vessel

•with own drive, coupling and base

•Capacity 1500 l/h

Three Screw feeders

•Production capacity: 1.000 kg/hr/each

•One for sugar powder, One for Cacao powder, One for milk powder

•Eachequipped with vibrating hopper to feed the pre-mixer / dry conch

•Feeding can be automatically controlled for each feeder by adding load cells to the pre-mixer/dry conch

Turbo mill CS 500

Production capacity: 300 to 500 kg/hr depending on the required micron of the milled sugar

TECHNICAL SPECIFICATIONS:

•Main drive 5.5kW

•Rotor speed 7500 rpm

•Grinding chamber diameter: 220 mm

•Power supply 400 Volt (+/- 10%), 3 phase, 50 cycles

Production process

Machine is equipped with a hopper feeding the granulated sugar to the grinding chamber through an adjustable orifice. The grinding chamber is composed of two grinding elements.

A turbo rotor element totally free of friction and a stationary element which is a ring sieve plates with perforation size 1.0 mm (could be amended on request) Self air cooling stream is insured by an intensive air flow through the grinding chamber. The cooling air is filtered through a cloth bag collecting the very fine sugar imported by the air stream. The mill is mounted on a steel table allowing a free space underneath to attach a plastic bag to collect the milled sugar

Pre- Mixer PREMIX (500-750-1000)

The stainless steel mixing vessel, provided with a rotating special stirrer with side scrapers

Provided in different batch capacities : 500 / 750 / 1000 kg

TECHNICAL SPECIFICATIONS:

•Main drive 4kW (for Premix 500 used for DO 1000)

•Stainless steel 304 jacketed tank

•Net volume 500lt

•Suction fan for evacuating acids gases

•Jacketed stainless steel piping

•Total weight 1.200kg

•Power supply 400 Volt (+/- 10%), 3 phase, 50 cycles

Production process

In following sequence ingredients such as fat, milk powder, cocoa powder, sugar, lecithin and other dry solids

have to be filled into the pre-mixer. During the mixing cycle, the pre-mixer makes a homogenous mass of the solids

and liquids. The side scrapers on the stirrer prevents that sugar will stick on sides of the vessel. When the mixing

cycle is finished the mixture will be pumped to the refiner ball mill.

Dry Conch MLDC (500-750-1000)

•same as pre-mixer but with following additions:

•More powerful main drive

•Different special design for the stirrer

•Stream of hot air with own heater and blower